Development of diffusion bonded large scale parts for highly stressed tool applications

Authors: Dr.-Ing. Jan Pfeiffer, Dipl.-Ing. Felix Gemse, M. Sc. Vanessa Frettlöh, Dipl.-Ing. (FH) Christian Kolbe, Dipl.-Ing. Udo Hinzpeter, Dr.-Ing. Simon Jahn, Udo Staps

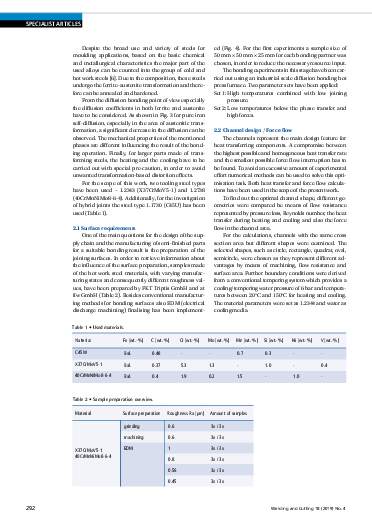

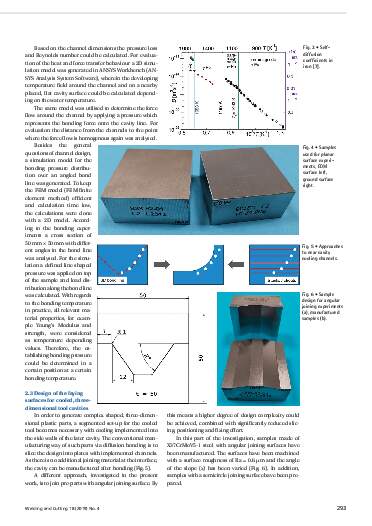

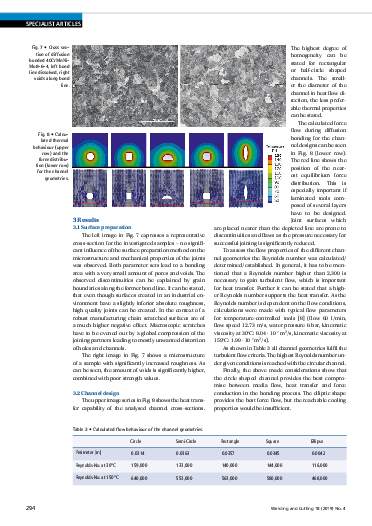

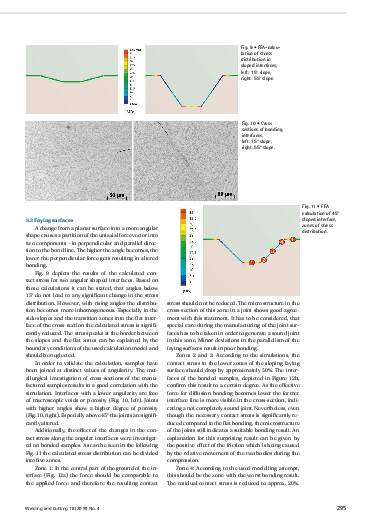

Due to rising demands on the quality and of the final

plastic product, it becomes increasingly important

to influence the thermal behaviour of the tools (e.g.

variothermal tempering). Due to this fact the geometry

of heat-control channels becomes very complex,

leading to a change in the manufacturing strategy of

large scale tools – manufacturing of a layered structure

and joining to the complete component. Even

though smaller parts can be joined by brazing, diffusion

bonding emerges as the promising method

for large scale, highly stressed parts as moulds or

distribution systems etc. However, in order to apply

diffusion bonding for such application, it becomes

necessary to understand the major influences and

up-scaling effects. In the present paper, first results of

a collaborative research between joining and tooling

institutes and companies will be shown. The aim of

this work is to use the understanding of process-relevant

influences for deriving a suitable diffusion

bonding related manufacturing chain. Combining

numerical simulations for the design of the channels

and tools with the thermal and mechanical behaviour

of the parts during bonding is one major part to gain

deeper insight and knowledge for diffusion-bonding

friendly design and processing. The data will be used

for a tooling design framework, which can be used for

several new developments without long-term fundamental

research. A validation and data gathering will

be carried out by the means of bonding samples up

to large sizes with varying design and manufacturing

history, generating broad experimental data for

up-scaling tasks. Microstructural changes will be analysed

and set into relation with the simulations and

applicatory requirements.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription