Reduction of flange widths in resistance spot welding by application of eccentric electrode cap geometries

Authors: Dr.-Ing. Christoph Böhne, Prof. Dr.-Ing. Gerson Meschut

DOI: https://doi.org/10.53192/WAC202203208

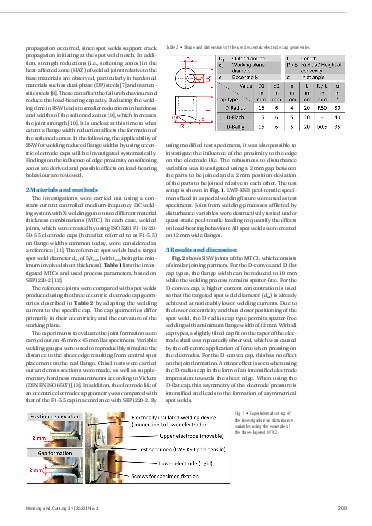

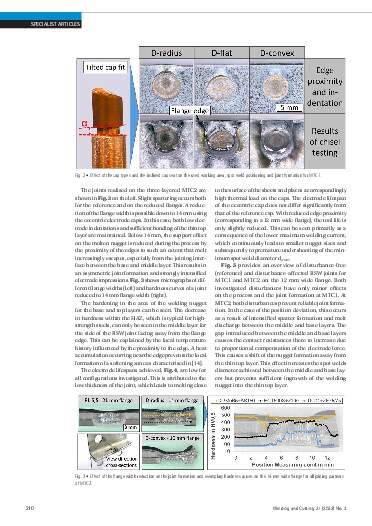

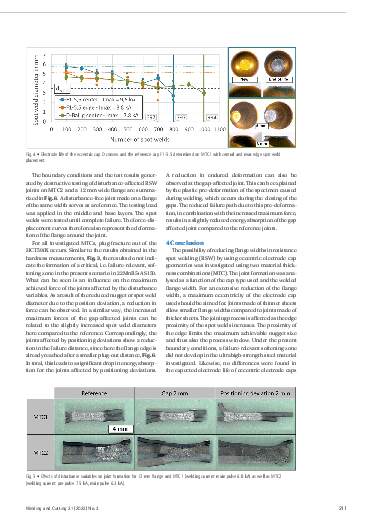

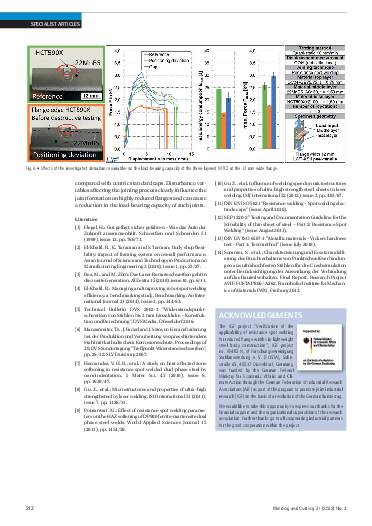

In automotive body construction, innovative lightweight design concepts using ultra-high-strength steel

variants are being used to meet legal requirements and constantly increasing demands. There is increasing interest in reducing flange widths commonly used today. In order to be able to continue using resistance spot welding, which is widely used in steel body construction, further knowledge on the process-side effects of a flange width reduction is required. In this context, the suitability of various eccentric electrode cap geometries for resistance spot welding of reduced flange widths and the influence on joint formation and load-bearing capacity are being investigated.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription