Weldability of advanced high strength steel drawn arc stud welding

Authors: Christopher Hsu, James W. Mumaw

This paper presents the findings of a weldability study of drawn

arc stud welding various advanced high strength steels (AHHS)

including Usibor, uncoated Boron steel and HC500C (DP800) of

various thicknesses and coatings from several automakers and

benchmarked against mild steel. M6 wide top (or large flange)

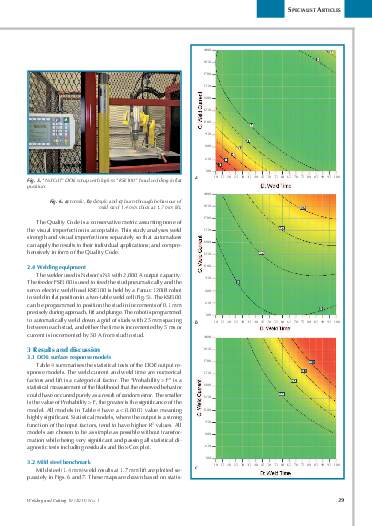

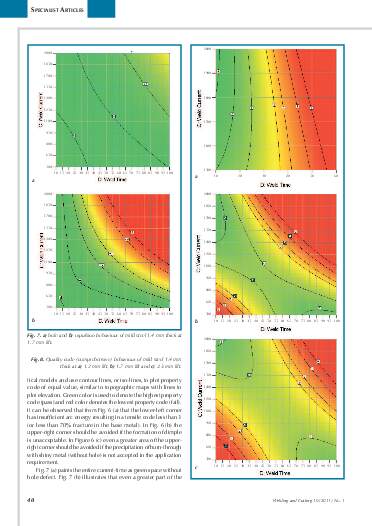

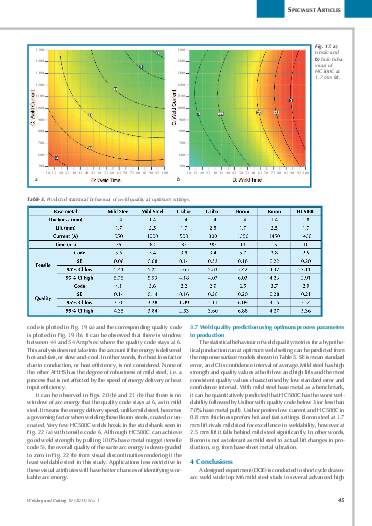

stud is used in the study. Instead of poking for a 9-box weld lobe

from trial-and-error, a robot is used to comb a 3D weld parameter

space of arc current, arc time and lift height, with a parameter

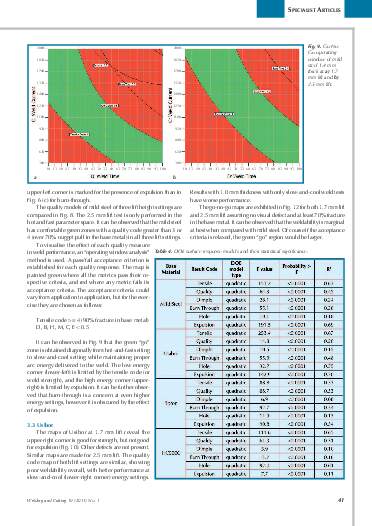

grid of 380 to 1,200 welds for each AHHS grade. A Design of Experiments

(DOE) approach maps out the relationship between

DOE inputs of control variables and DOE outputs of weld quality

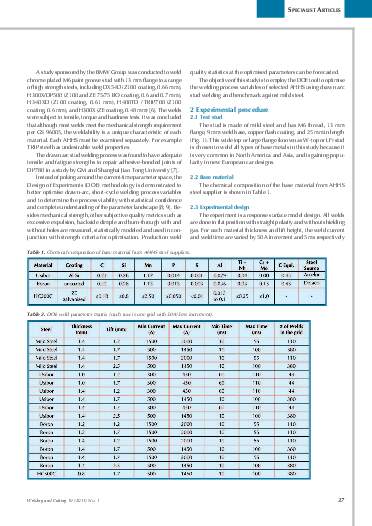

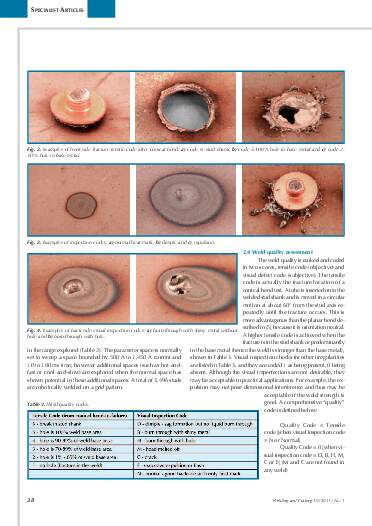

statistically. The objective and subjective weld quality are measured,

including destructive conical bend for weld strength, dimple,

sag, burn-through, head melting, cracking, excessive expulsion

and backside marking.

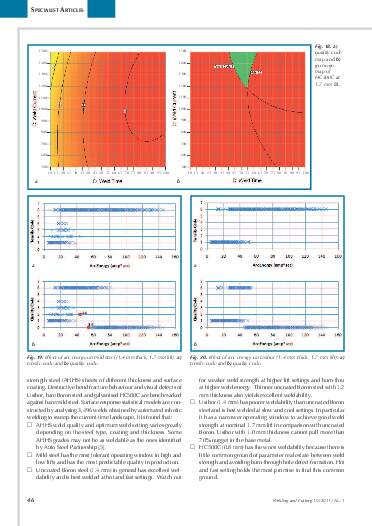

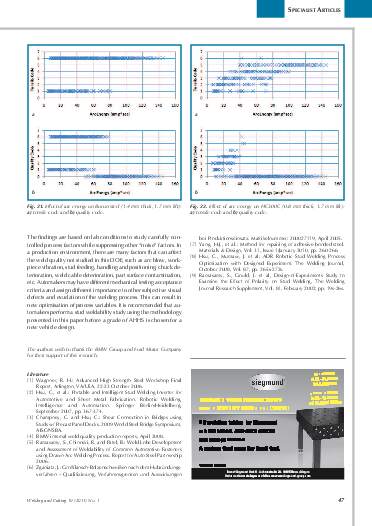

Among the 3,496 welds visually classified, photographed from

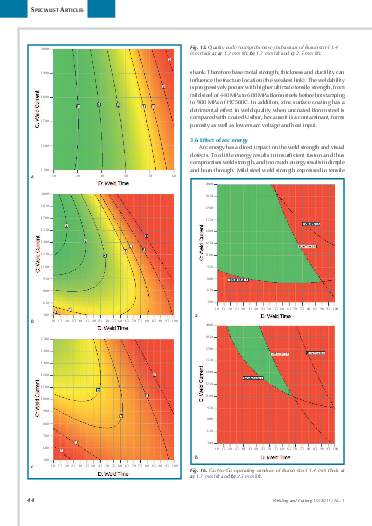

both sides and destructively tested, it is found that not all AHHS

behave the same in drawn arc welding. AHHS of different type,

thickness and coating exhibits different welding characteristics.

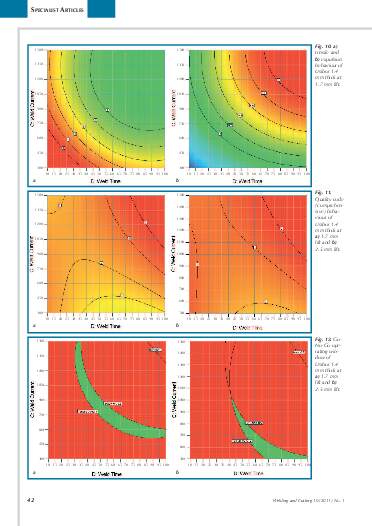

Mild steel as a baseline has the classic C or kidney shaped operating

lobe and the best weldability characterised by the largest

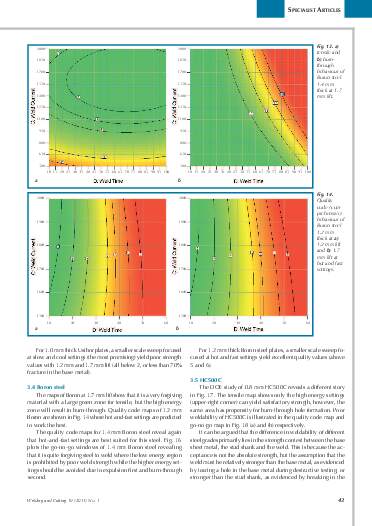

lobe size and tolerance to lift. Uncoated Boron steel of 1.2 mm

and 1.4 mm thickness has excellent weldability at lower lift, with

deteriorating performance at higher lift. It is best welded at hot

and fast settings. Usibor of 1.4 mm thickness has marginal weldability.

It is best welded at slow and cool settings. At 1.0 mm

thickness it cannot pull 70% nugget at optimum settings. HC500C

of 0.8 mm thickness has unacceptable weldability but shows potential

in very hot and fast settings.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription