Combined laser beam welding and laser powder cladding on stainless steels for protection against intergranular corrosion

Authors: Dr.-Ing. Niklas Sommer, Prof. Dr.-Ing. Prof. h. c. Stefan Böhm

DOI: https://doi.org/10.53192/WAC202204288

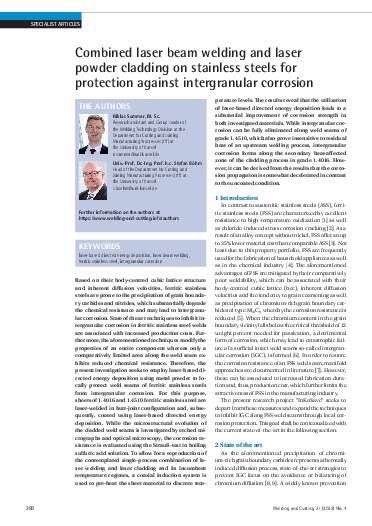

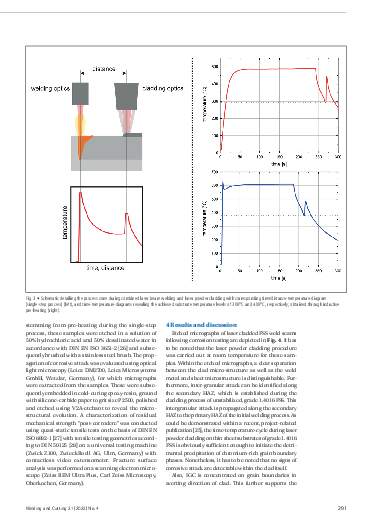

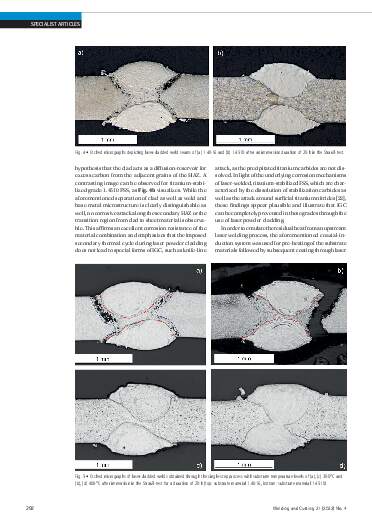

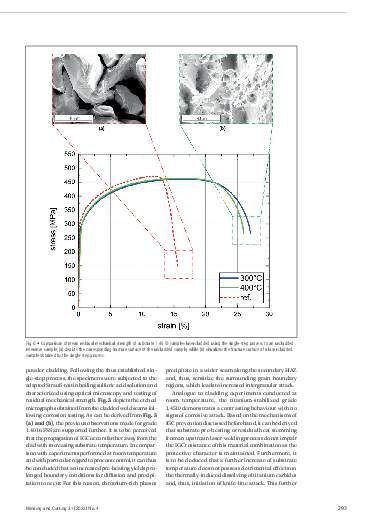

Based on their body-centred cubic lattice structure and inherent diffusion velocities, ferritic stainless steels are prone to the precipitation of grain boundary carbides and nitrides, which substantially degrade the chemical resistance and may lead to intergranular corrosion. State of the art techniques to inhibit intergranular corrosion in ferritic stainless steel welds are associated with increased production costs. Furthermore, the aforementioned techniques modify the properties of an entire component whereas only a comparatively limited area along the weld seam exhibits reduced chemical resistance. Therefore, the present investigation seeks to employ laser-based directed energy deposition using metal powder to locally protect weld seams of ferritic stainless steels from intergranular corrosion. For this purpose, sheets of 1.4016 and 1.4510 ferritic stainless steel are laser-welded in butt-joint configuration and, subsequently, coated using laser-based directed energy deposition. While the microstructural evolution of the cladded weld seams is investigated by etched micrographs and optical microscopy, the corrosion resistance is evaluated using the Strauß-test in boiling sulfuric acid solution. To allow for a reproduction of the contemplated single-process combination of laser welding and laser cladding and its incumbent temperature regimes, a coaxial induction system is used to pre-heat the sheet material to discrete temperature levels. The results reveal that the utilization of laser-based directed energy deposition leads to a substantial improvement of corrosion strength in both investigated materials. While intergranular corrosion can be fully eliminated along weld seams of grade 1.4510, which also prove insensitive to residual heat of an upstream welding process, intergranular corrosion forms along the secondary heat-affected zone of the cladding process in grade 1.4016. However, it can be derived from the results that the corrosion propagation is somewhat decelerated in contrast to the uncoated condition.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription