Investigation and further development of friction welding for joining additively manufactured components

Authors: Dr.-Ing. Marcel Hatzky, Prof. Dr.-Ing. Prof. h. c. Stefan Böhm

DOI: https://doi.org/10.53192/WAC202202104

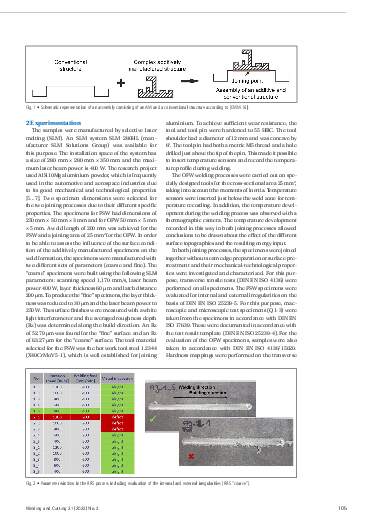

For the industry additive manufacturing (AM) has the potential to produce components with complex geometries in relatively short lead times and at comparatively low cost, even with batch size 1. A major limitation for the application of additive manufacturing as an industrial manufacturing process is the limited component size. The continuous request to overcome part size limitations of additive components leads to use for welding processes to join additively manufactured

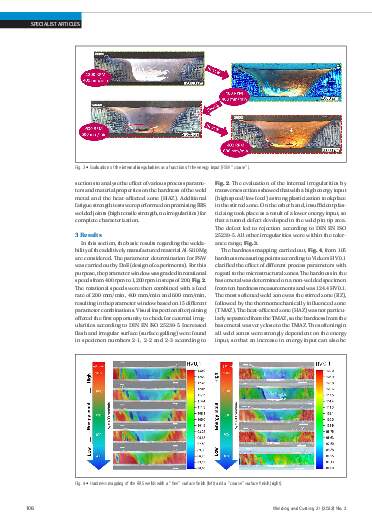

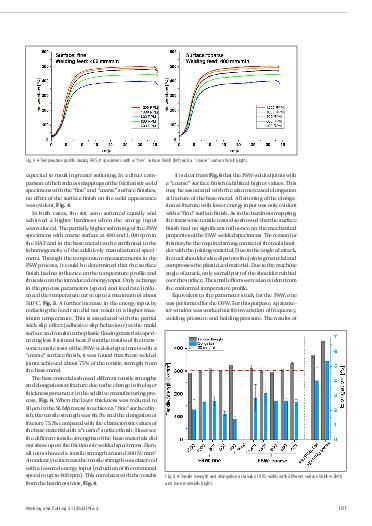

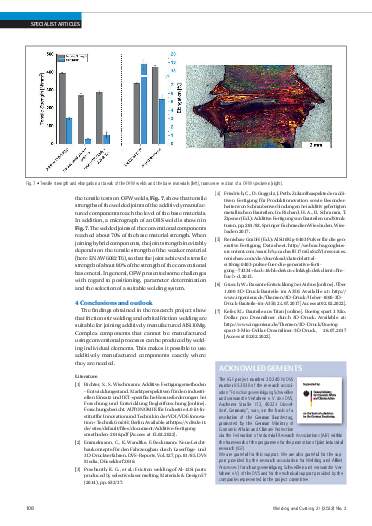

components both to each other and to wrought or cast alloys. In the research project, friction stir welding (FSW) and orbital friction welding (OFW) are used to join selectively laser melted (SLM) AlSi10Mg components. The presented work aims to minimize the number of pores in the welds as well as to limit the strength degradation in the joining area. By using the friction-based processes, processing the AM components directly without seam edge or surface pretreatment should be possible. It could be proven that the susceptibility to pores in the weld seam is significantly reduced and AM parts with lower component weight (samples fine) can be welded without defects. The results show the weld edge quality has no striking influence on the mechanical-technological properties of the joint.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription