An experimental study on the control and signifi cance of zinc porosity in arc welding of zinc coated steel in automotive chassis

Authors: Carlota Arenillas, CEng Mike Bell, José A. Ravelo

DOI: https://doi.org/10.53192/WAC20220298

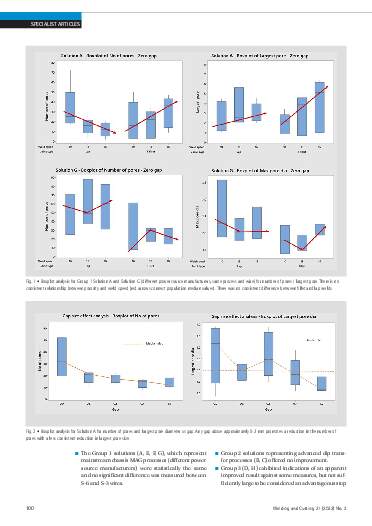

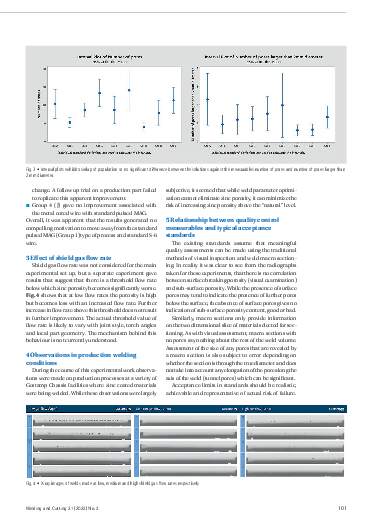

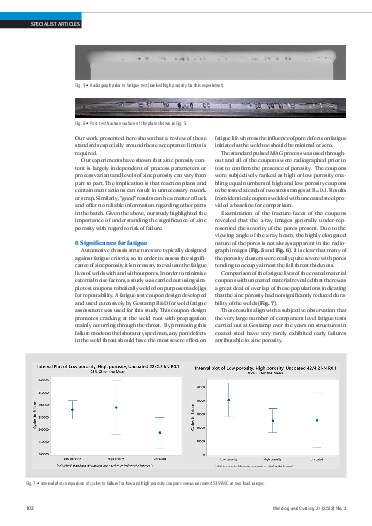

A continuing automotive industry trend towards increased use of galvanized steel in chassis structures has generated big challenges regarding the in-production assessment and control of zinc porosity defects in arc welds. The objective of this study was to investigate, in a systematic way, whether it is possible to eliminate or significantly reduce the amount of zinc porosity in MAG welds by optimization of weld parameters or by use of alternative MAG process variants and weld wires. A review of the traditional weld quality sampling methods found that they struggle to represent the true extent or severity of zinc porosity in welds. Our experiment results concluded that alternative MAG weld variants, special parameters or novel weld wires could not eliminate or very significantly reduce zinc porosity content, compared to current standard practice. However, we have shown that the significance of zinc pore defects on fatigue durability is actually very low so we suggest it may be more cost effective to adjust safety factors, in critical welds only, in the design analysis process.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription