Welding ferrous metals: How can you be sure of accurate preheat?

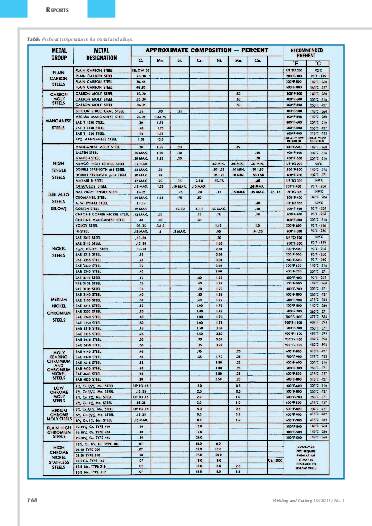

Preheat is frequently required for most

welding applications. A major part of the

equation is temperature indicators, to ensure

the recommended level of preheat has been

achieved. Welders know – and ASME codes

reinforce – the need for preheating of many

ferrous metals prior to welding. A successful

weld unites the welding filler metal and the

base-metal into one entity; a good weld is

at least as strong as the base materials being

joined. With many materials bringing the

base metal “up to heat“ before welding improves

the chances of achieving a successful

weld by reducing the danger of crack formation

and other problems. As a result,

there is less need for factory rework, and

performance of the finished piece is enhanced.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription