Flexible bonding of flexible hybrid plastic bipolar plates

Authors: Dipl.-Ing. Dennis Weiser, Dipl.-Chem. Elisabeth Stammen, Prof. Dr.-Ing. Prof. h. c. Klaus Dilger, Dipl.-Ing. Sebastian Brokamp, M. Sc. Fabian Bergenthun, Dr.-Ing. Jörg Karstedt, Dr. Ing. Peter Beckhaus

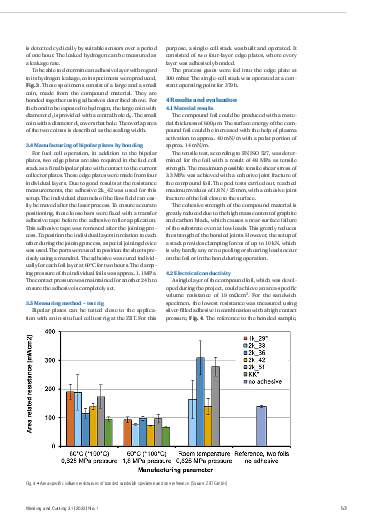

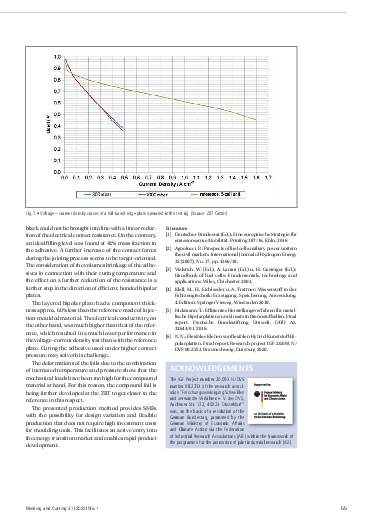

The production of graphitic bipolar plates by building them up layer by layer from individual flexible foils, instead of preformed halves, represents a new manufacturing approach. Five layers of a special compound foil were individually cut with a CO2 laser according to a previously constructed cell design and joined into a bipolar plate with the help of adhesives. Selected epoxy resin adhesives, acrylate pressure-sensitive adhesive tapes and polyolefin hotmelts were tested for their suitability in the fuel cell environment with regard to electrical conductivity, chemical resistance and hydrogen impermeability. The bonded, foil-based bipolar plate showed significantly higher electrical contact resistances than the injection-moulded reference. In the test rig, such a bipolar plate was successfully operated for 379 h under fuel cell operating conditions without any leaks occurring.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription