Investigation and optimization of process parameters and tools for underwater bonding of brackets

Authors: M. Sc. Lemmrich Luzie, Eng. Leandro Vaccari, M. Sc. Linda Fröck, Prof. Dr.-Ing. Wilko Flügge, Dr.-Ing. Thomas Hassel

DOI: https://doi.org/10.53192/WAC20230250

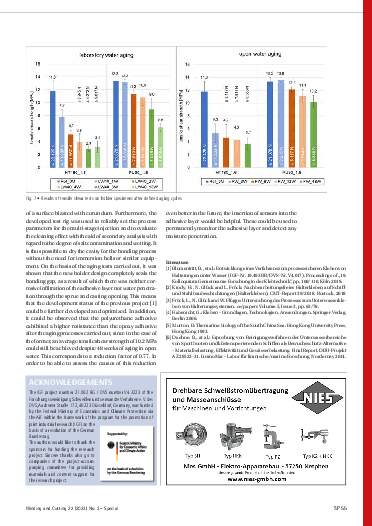

The research project presented here provides an advanced process for the adhesive underwater bracket joining. As an alternative to the previously established underwater welding process, it comes with a number of benefits, such as low heat input, no damage or weakening of the components to be joined, and fewer risks for divers. In order to make the bonding process for the subsequent retainer attachment safer and more repeatable, a prototype for performing a multi-step injection process was developed within the scope of this project. Various process parameters were analyzed and adjusted at the Fraunhofer IGP to achieve strong adhesion. Based on this knowledge, a demonstrator tool for manual and semi-automated bonding under water was developed. This is being tested in realistic trials by divers

in the UWTH water basin. To investigate the aging of the adhesive layer in a wet environment, holder samples were stored in laboratory as well as open water and then tested in a tensile shear tests.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription