Electron beam welding and brazing in atmosphere with reduced accelerating voltage on aluminium alloys susceptible to hot cracking

Authors: M. Eng. Aleksej Senger, M. Sc. Georgii Klimov, Dipl.-Ing. Alexander Beniyash, Dr.-Ing. Thomas Hassel, Dr.-Ing. Simon Olschok

DOI: https://doi.org/10.53192/WAC202204272

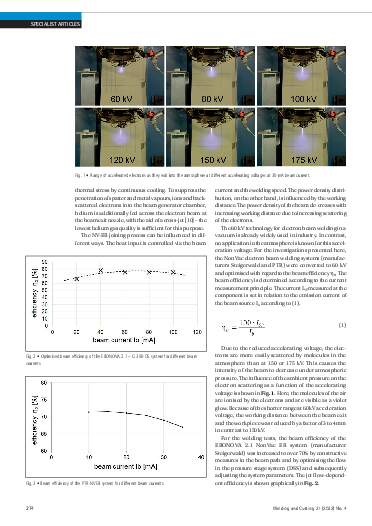

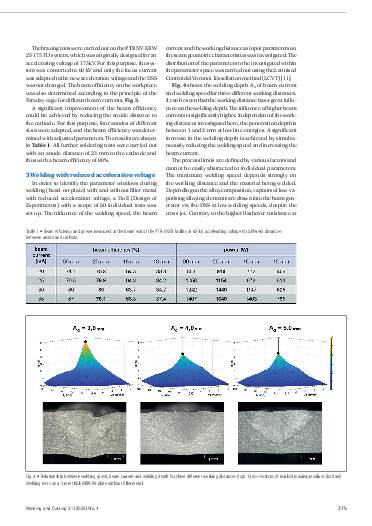

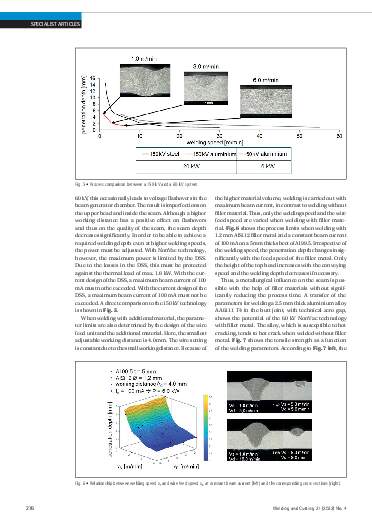

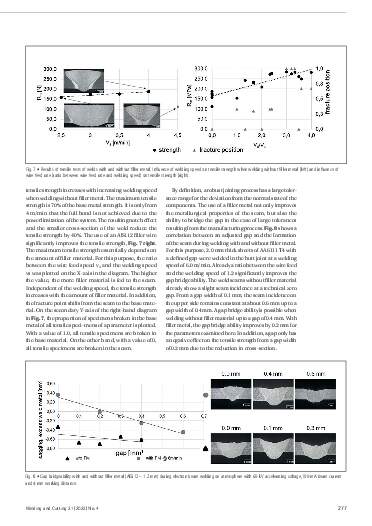

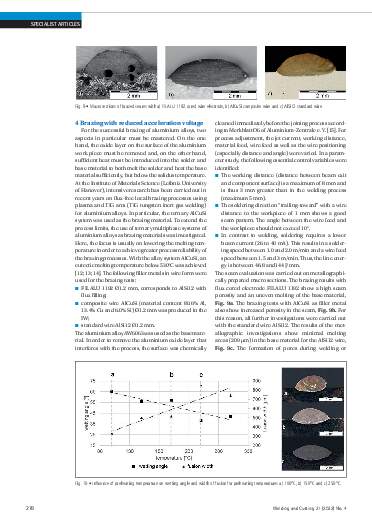

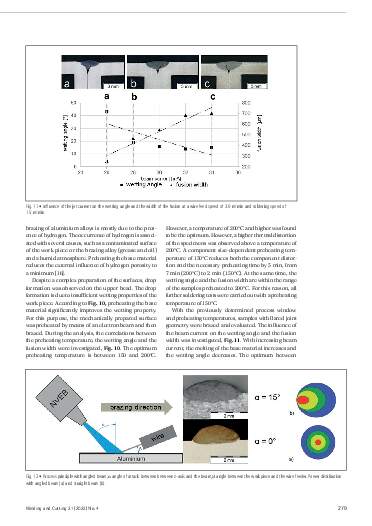

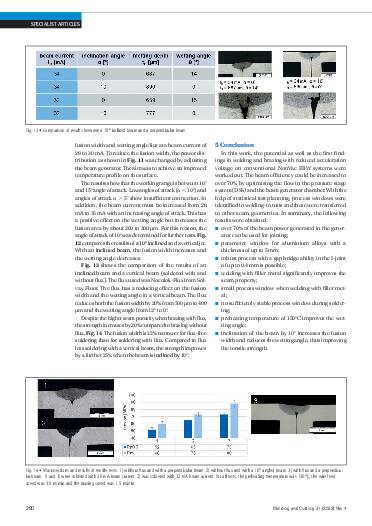

The electron beam welding process in the atmosphere is characterised by a high process speed as well as an energy input that is independent of the material, surface properties and angle of incidence with minimal distortion. In addition, the atmospheric process offers the advantage over the vacuum process that the process is not bound to a vacuum work chamber and the beam offers good gap bridge ability due to the higher scattering in the atmosphere and enables reliable melting of the welding wire. In contrast, systems with voltages of up to 175 kV are operated to accelerate the electrons. The resulting kinetic energy is largely converted into heat when the electrons hit the work piece surface. The deceleration of the electrons also causes X-rays to be emitted. This results in high demands on X-ray protection. A reduction of the acceleration voltage minimises the necessary radiation protection and improves the flashover safety in the generator, even when processing easily vaporisable materials. At the same time, the potential of a narrower design of the beam generator, which results in a significant weight reduction compared to conventional electron beam technology and thus enables robotic use, is very high. In the triode system with 60 kV acceleration voltage, the electron velocity is sufficient to provide the necessary energy density at the joint (soldering and welding with filler material). In the investigations on which the article is based, a process window was worked out for the joining of aluminium in the thin sheet range, process-related proper-ties were identified and compared with those of high-voltage technology. For this purpose, metallographic and mechanical investigations were carried out and the previously determined parameter windows were transferred to the joining of aluminium alloys susceptible to hot cracking in I-joining.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription