Manufacture and investigation of twochamber flux-cored wires for continuous underwater wet welding

Authors: Dr.-Ing. Ivan Lendiel, Dipl.-Ing. Jan Klett, M. Sc. Thomas Wolf, M. Sc. Emily Schmidt, Eng. Leandro Vaccari, Dr.-Ing. Thomas Hassel

DOI: https://doi.org/10.53192/WAC202204296

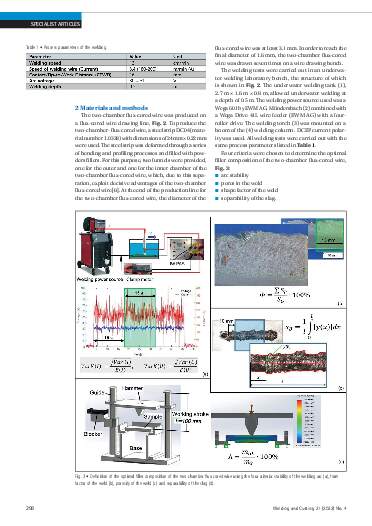

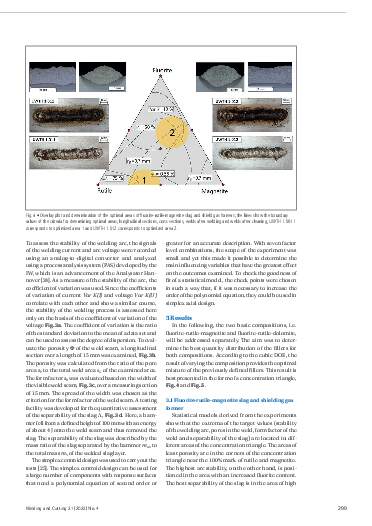

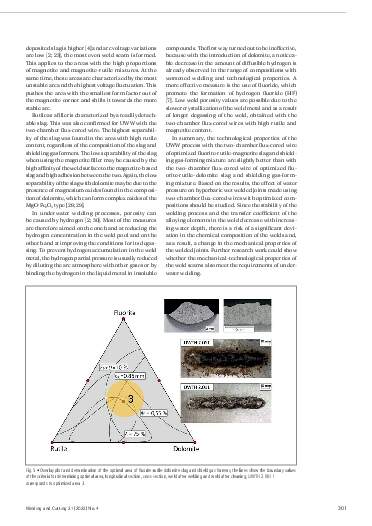

Wet manual arc welding is a typical joining process for underwater welding. In most cases, stick electrodes are used when wet welding has to be carried out. A continuous welding process contributes to improving the divers work performance by minimizing the starting points, consequently reducing the sources of error and therefore the workload and costs. Scientific work in this field is performed at the Institute of Material Science (Leibniz University Hannover), where promising results have been achieved developing flux-cored wire and the necessary technology of underwater wet welding. In this article investigations of welding properties (stability, porosity, form factor and separability of the slag) of the two-chamber fluxcored wire are presented. The optimal ratio of shielding gas and slag-forming fillers of the three-component mixtures “fluorite-rutile-magnetite” and “fluorite-rutile-dolomite” were determined and the respective two-chamber flux-cored wires were manufactured and tested.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription