Development of an online quality assurance method based on acoustic emissions using magnetic pulse welding

Authors: Markus Graß, M. Sc. Carsten Bruckhaus, Hans-Hermann Kaufmann, Dr. Hubertus Siebald, Dipl.-Ing. agr. MEng Quality Management Boris Kulig, Prof. Dr.-Ing. Prof. h. c. Stefan Böhm, Prof. Dr. Oliver Hensel

DOI: https://doi.org/10.53192/WAC202203214

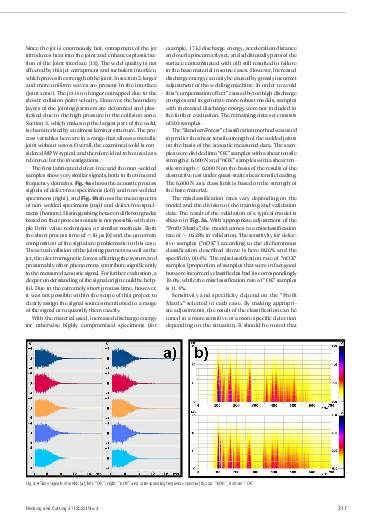

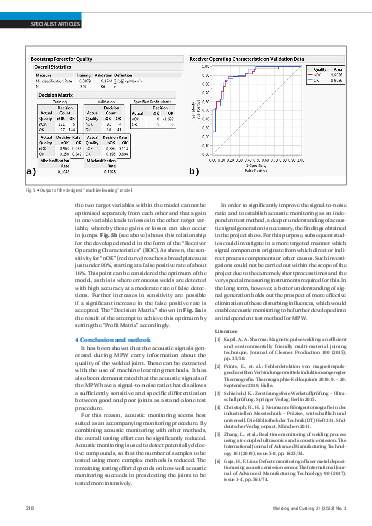

A reliable easy-to-implement process monitoring can offer great opportunities for the implementation of modern joining processes in industrial environments. Ideally, the quality of the joint is already predicted during the joining process. This eliminates the need for subsequent testing procedures, which results in cost and time savings. Magnetic pulse welding (MPW) is becoming increasingly important because, as a representative of the pressure welding processes, it is capable of producing dissimilar metallic joints quickly and cost-effectively. However, the MPW process is currently mainly monitored using post-process inspection methods, e.g. ultrasound or thermography. The online quality assurance method that is

presented here is based on the analysis of acoustic emissions. The sound data from the MPW process is

processed using a machine learning (ML) model, since classical analysis methods did not provide sufficient results due to the MPW process characteristics (short process time and unfavourable signal-to-noise ratio). With an ML model, a classification rate of 84% could be achieved.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription